Driving Simulators

As vehicle simulation technologies become more advanced and crucial for engineering next generation vehicles, it is still impossible to fully evaluate and tune new features without the input from human drivers. Traditionally, driver evaluation was the last step in the product development process because it requires a completed vehicle. Mechanical Simulation is committed to provide Driver-In-the-Loop technologies in all or our products to support human subjective analysis at any point in the development process. These products, developed by Mechanical Simulation or our driving simulator partners, range from inexpensive desktop simulators to multi-million-dollar motion platforms and 360-degree visualization systems.

Mechanical Simulation has been controlling driving simulators for more than 20 years and our CarSim, TruckSim, and BikeSim software is the vehicle dynamics engine in over three thousand driving simulators used in hundreds of different applications.

Entry Level Simulator Options

Driving simulators with game-quality desktop mounted steering wheels and pedals can be vital for both engineering and driver training type applications. These can be your only simulator or can be used as support devices for a large simulator facility. A couple of applications for these simulators include:

- Controller evaluation – all of our products use the same solver, vehicle data, and control interfaces. This means you can drive your active control and ADAS algorithms at any point in the design process and evaluate basic functionality, error conditions, and find edge-cases that can be difficult to find by reading output plots. Fine tuning your design using inexpensive hardware can save thousands of dollars and significantly reduce time to production. Our DS products and our Unreal Engine plugin both support a variety of game quality pedals and both have a Simulink interface for you connect your own technology to the simulator.

- Driver training – low-cost simulators cannot replace the physical driving experience, but they are frequently used by beginning and professional drivers to learn the nuances of a new proving ground or racetrack. In a world where practice-makes-perfect, simulators are a great tool to learn and practice with low-risk and low-cost. Frequently these simulators are used in facilities that also have an expensive motion-based driving simulator. In this case, the low-cost simulator can be utilized to prepare future projects, while the large, expensive simulator remains in use.

Office Space Simulators With No or Small Motion

The next step up in the driving simulator world provides a seating environment and driver controls that are similar to those used in real vehicles. Typical simulators in this category provide a 180+ degree field of view or a VR headset. Higher quality driver controls provide more realistic pedal feel and steer torque than gaming hardware and the motion system provides onset cues that help drivers evaluate lateral and longitudinal performance in a small footprint. These simulators can be typically run and driven by a single individual.

|

|

| Ansible Motion Theta simulator | VI-grade COMPACT simulator |

Small, full-motion driving simulators

This is the simulator category that provides six degrees of motion typically provided by a hexapod motion platform. These simulators provide complex washout algorithms and filters that transfer vehicle motions, so the driver feels vehicle motions with as much realism as possible. These simulators run the vehicle solver in soft-real-time on Windows or hard-real-time using a hardware in the loop (HIL) operating system that can run real controllers on the simulator. These simulators typically require a small team of engineers and drivers to safely operate.

|

|

| A render of the Cruden AS3 car Hexapod system | CarSim DS running on a hexapod driving simulator |

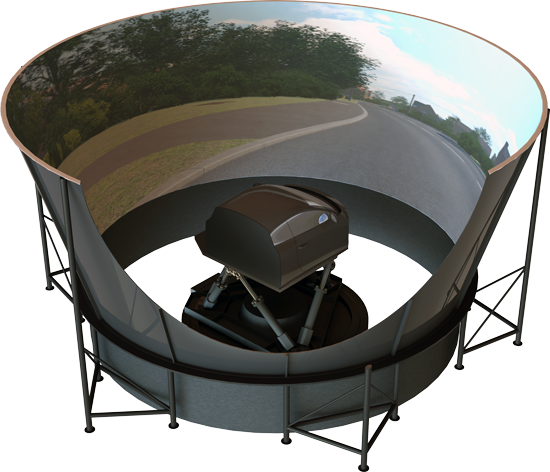

Large Facility, Large Motion Simulators

These simulators have a larger performance envelope, and multi-projector, 180 degree+ visualization systems and are designed to produce sustained accelerations that closely represent actual vehicle motions. These simulators include at least six degrees of motion and as many as 9 degrees of freedom. Mechanical Simulation supports several manufactures of these systems through our partner program.

|

|

| Ansible Motion Delta simulator | VI-grade DiM 150 9-DOF simulator |

VehicleSim Products

CarSimTruckSim

BikeSim

SuspensionSim

Built-In Features

ADAS: Moving Objects and SensorsAnimation and Plotting

Automation and COM

Built-In Controllers

GUI, Database, and Documentation

Modular VS Math Models

Paths and S-L Coordinates

Roads and Terrain

VS Commands Language

VS Scene Builder Tool

Co-Simulation Technologies

Real-Time HIL SupportSimulink, FMI/FMU, LabVIEW

Unreal Engine

VehicleSim SDK